PROCESS AND ENGINEERING SERVICES

As a vertically integrated manufacturer of opto-electronic components, APIC is ready to leverage its experience in design, wafer fabrication, packaging, and integration to offer best in class Process and Engineering Services to help you achieve your design goals. Contact APIC sales (sales@apichip.com) to see how we can help you achieve your design goals.

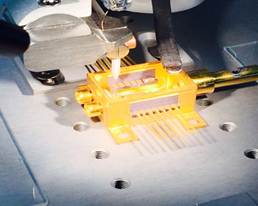

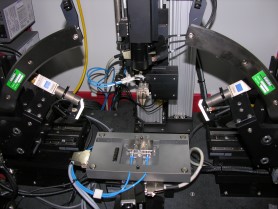

Laser Welding

With an alignment efficiency of greater than 95%, APIC is able to laser weld in-package with our two-beam laser welder and omega-shaped clips.

We can work with fiber ferrules between 0.9 – 1.2 mm.

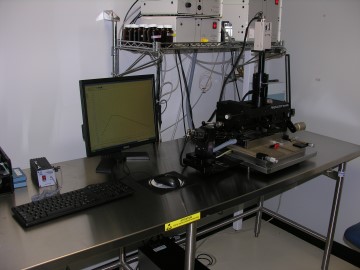

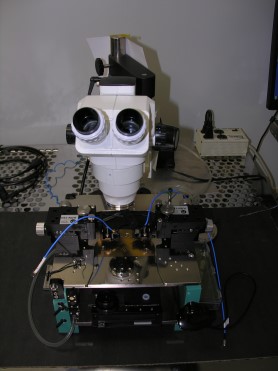

RF Testing

Tests we can run on photodiodes:

- Vf & VBr

- IDk

- Responsivity

- Saturation

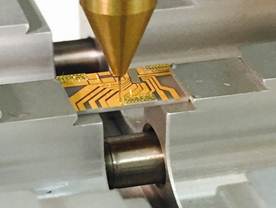

Wafer Dicing

APIC delivers the ability to cut wafers between 1 and 8 inches in diameter.

We can cut many materials, but the wafers we primarily cut are :

- Si

- AlN

- SiC

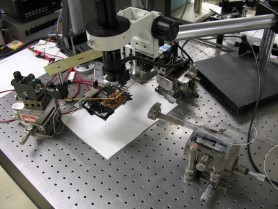

Wirebonding Tests

APIC performs wire pull, ball shear, and die shear tests!